PFAS regulations in workwear: What every QHSE manager needs to know

PFAS are attracting considerable attention. Their potential impact on human health and the environment is leading to stricter regulations worldwide and increasing pressure to find alternatives. At the same time, the protection of the wearer remains essential – and PFAS still play an important role in that regard. In this article, we outline the facts, standards, and trade-offs so that you, as an QHSE manager, can make well-informed decisions.

What are PFAS?

PFAS stands for per- and polyfluoroalkyl substances – a family of thousands of man-made chemicals. They are water, grease, and dirt repellent and are used in a wide variety of products such as pans, firefighting foam, and technical textiles. In workwear, PFAS are employed in fluorocarbon finishes and ePTFE membranes to provide protection against moisture, oil, and liquid chemicals.

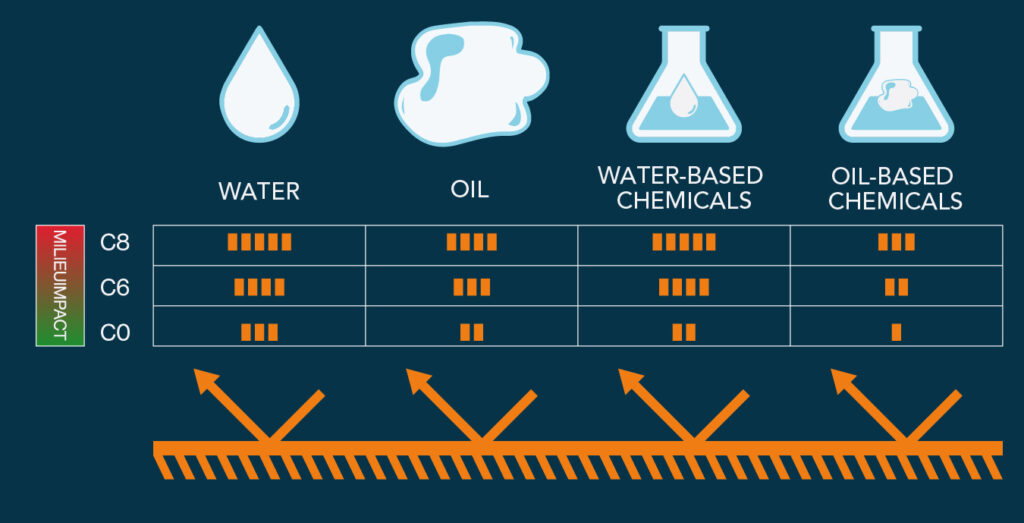

Various generations of fluorocarbon finishes have now been developed:

- – C8: older generation, with proven harmful environmental impact

- – C6: improved environmental performance, but still contains PFAS

- – C0: completely PFAS-free, but limited effectiveness against oil and solvents

The C0 variant is suitable for protection against water, but not against oil-based substances. As a result, its performance according to standards such as EN 11611 and EN 11612 (E) is not always sufficient.

Why is PFAS used in workwear?

Protective workwear must meet high standards – especially in environments where hazardous substances are present. PFAS help make the clothing repel dirt and liquids. In addition, they protect against oils and solvents. This is necessary to comply with standards such as EN13034 and EN11612. Without these properties, chemical substances could penetrate the fabric, exposing the wearer to various risks.

What are the regulations regarding PFAS?

The European standard EN13034 is the leading guideline for workwear that must provide protection against liquid chemicals. This standard sets requirements for the:

- – Barrier performance of the fabric and seams

- – Resistance to liquid penetration and repellency

- – Testing with chemical substances (water and oil based)

Note: EN13034 offers limited protection. For higher risks, a more robust standard such as EN14605 is required (for example, for gas or vapor protection).

How is this protection tested?

The main test under EN13034 is the Gutter test (according to EN 6530). In this test, 10 ml of liquid is poured onto the test fabric over a period of 10 seconds. The fabric is positioned at a 45-degree angle on the absorbent material. The percentage of liquid that penetrates is measured (the penetration index), and the amount of repelled liquid is recorded (the repellency index).

Four chemicals are tested. Oil-based chemicals include o-xylene and butanol, while water-based chemicals include caustic soda (10%) and sulfuric acid (30%). A fabric passes if, for at least one chemical, the penetration is ≤ 1.0% and the repellency is ≥ 95%.

The Future of PFAS in Workwear

The future is clear: PFAS must disappear. However, in practice, the situation is more complex. For oil-based substances, there is not yet a fully viable alternative that ensures the safety of the wearer. Fortunately, workable alternatives have been developed for water-based substances. Therefore, careful consideration is required for each application. The central question remains: does a PFAS-free finish still provide sufficient protection against the substances the wearer is exposed to?

European Legislation: REACH and the Ban

PFAS regulation falls under REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals). Under this regulation, PFAS in the clothing industry is being phased out. It is expected that starting in 2025, there will be a general ban on the use of PFAS in clothing. There is an exemption until 2037 for PPE class III clothing (such as EN13034) due to its essential protective function. This means that the use of PFAS will still be permitted for workwear that meets certain protective standards – but only if it is truly necessary.

What does this mean for your organization?

Every application is different. That is why it is important to know which substances are present in your work environment. If it concerns water-based substances, then a PFAS alternative works perfectly; however, if it involves oil-based substances, PFAS is still necessary. Are you unsure whether your clothing still complies – or whether you can switch to PFAS-free alternatives? We are happy to work with you.

Together, we can determine what is acceptable and what is not. Please feel free to contact us.